| Model | HM-RRS30 |

|---|---|

| Tube Shape | Circular Tube |

| Min Length | 150mm |

| Max Length | 6000mm |

| Min Diameter | 2mm |

| Max Diameter | 40mm |

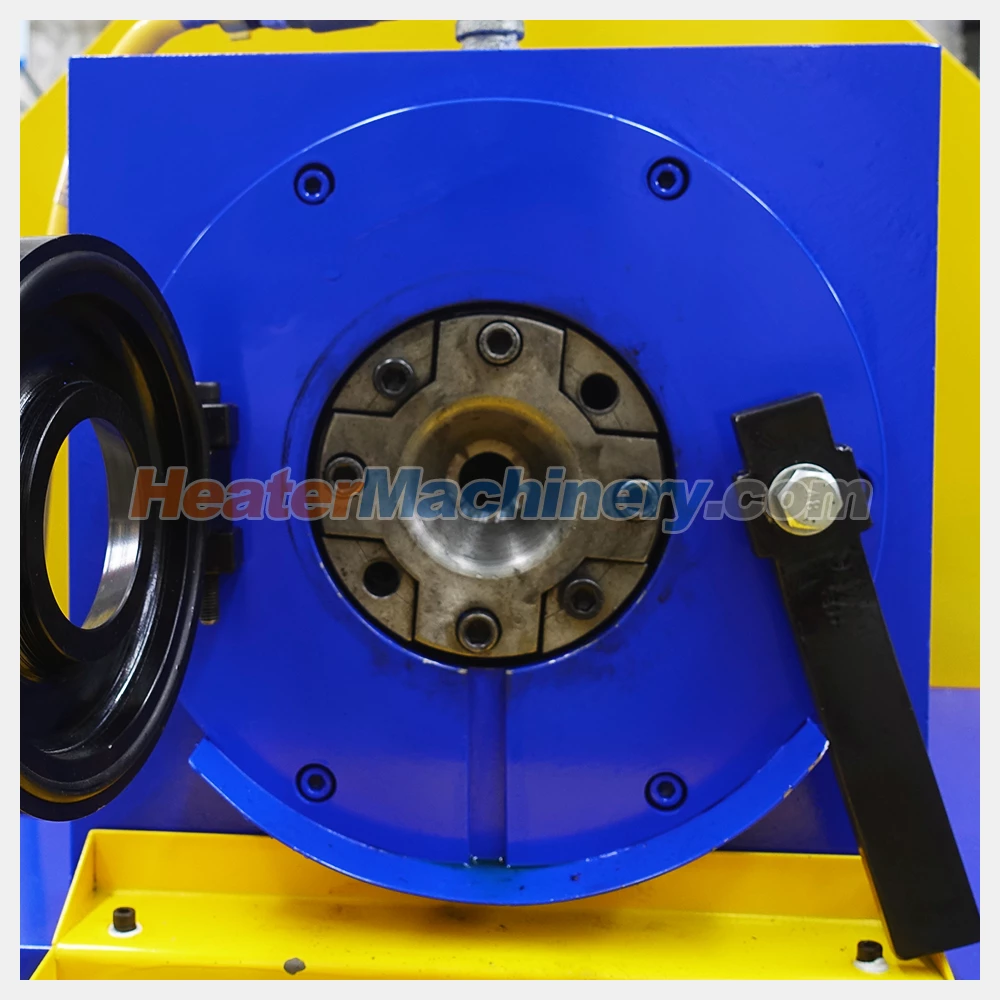

The HM-RRS30 Round Tubes Swagging Reducing Machine is a precision-engineered industrial solution designed for producing high-density heating elements. Tailored for small-batch and multi-size manufacturing, it streamlines the production of cartridge heaters, double-end tubular heaters, and hot runner heaters. Its modular mold system ensures rapid adaptability to diverse production requirements.

Features

Applications

Technical Specifications

Mold Configuration: 4-piece modular set (included).

– These specifications are based on the “standard specifications” or “with certain optional equipment.”

– The above specifications are subject to change without notice for quality improvement, and the video, illustrations and photos on this page may differ slightly from the actual product in terms of color.

Do you have inquiries

regarding HM-RRS30 products?

If you need more machines for manufacturing heating elements,

please email me your detailed requirements.

HeaterMachinery, part of BOSI Supply Chain Ltd., a leading supplier of high-quality heating element machinery, offering tailored solutions for manufacturing heating elements. We provide efficient, reliable, and energy-saving equipment for industries worldwide.

Copyright © 2025 BOSI